WinSoft offers high channel count, modular, and scalable Data Acquisition (DAQ) and control systems |

| ||||||

|

Our DAQs are used in aerospace, defense, industrial, and commercial applications.

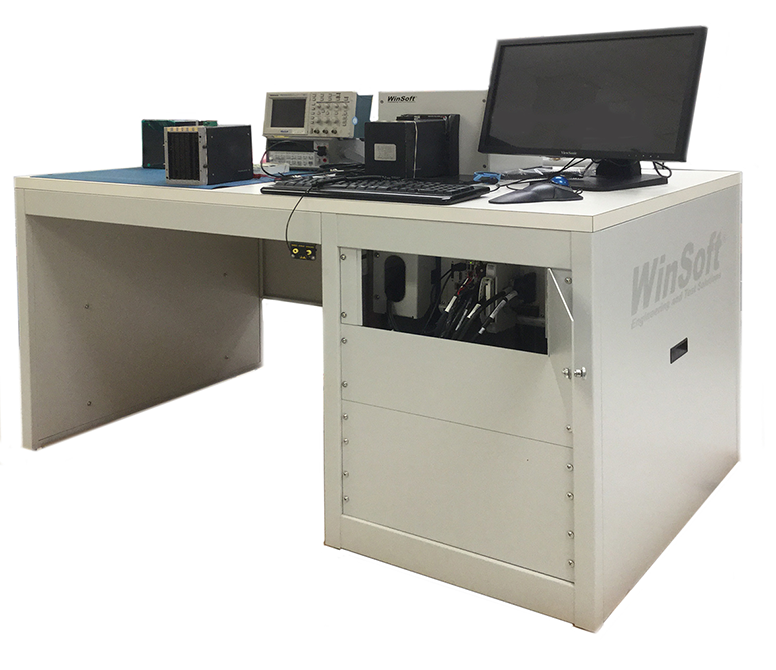

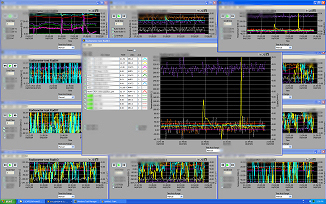

With these DAQ systems, you can acquire and digitize signals from variety of sources and sensors, store the data, analyze it, and present the results in local and remote locations. Additionally, our DAQ systems include optional control capabilities such as closed-loop PID control, analog outputs, and discrete on/off controls. Many of our DAQ solutions are delivered as a turn-key system based on customers’ requirements. Our DAQ systems provide the highest performance in accuracy, precise timing and synchronization, signal conditioning, and can support virtually unlimited channel-count. You can choose from stand-alone operation or remote control options. WinSoft is a National Instruments (NI) Gold Alliance Partner and our DAQ systems are mostly based on National Instruments’ hardware and software platforms. Our 18 years of strategic partnership with National Instruments allows us to include the highest performance and top quality DAQ related hardware and software available on the market. Features

|

Real Time and FPGA based DAS

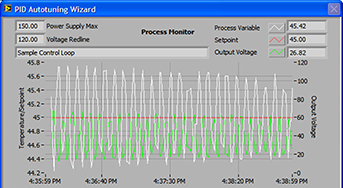

For DAQ systems that need fast data acquisition and massive calculations, WinSoft developed a LabVIEW Real Time and FPGA architecture that enables monitoring and control of various signals. A companion PID toolkit enables flexibility in adjusting the parameters per your project's requirements.

Typical Measurements

|

|

Industries

|

|

Example - Large channel count DAQ System for Environmental Testing of a Spacecraft and a Satellite

A satellite manufacturer tasked WinSoft to design, develop, and build a computerized data acquisition (DAQ) and control system for the environmental testing of spacecraft and satellite in a thermal vacuum chamber. Our customer required to record the data continuously every few seconds over a period of several months.

The following were the main system requirements:

- Monitor up to 2,000 temperature sensors and 10,000 telemetry and command signals of various types.

- Perform user-defined calculations on the acquired data in real-time and control up to 200 heaters based on the temperature readings and the calculations results.

- Store the acquired data and status information and display the results in a highly configurable GUI.

- Seamlessly integrate into the DAQ system 250 PID control loops that would run in parallel with the measurements tasks.

- Allow the operator to view up to 10 different windows with various graphical and image displays in real time.

- Link requirements documents to test and control applications.

- Enable several DAQs to run independently while acquiring and storing the data in a central database.

WinSoft designed, integrated, and built several systems using the following hardware and software components:

- NI PXI platform and several NI SCXI chassis for data acquisition and control.

- A host-server PC for data storage, communication, and user access management.

- Multiple client PCs for display and GUI.

- LabVIEW Real-Time and FPGA Modules and the LabVIEW PID Control Toolkit to implement the control algorithm.

- Several SCXI multiplexer modules that route the sensor inputs to PXI DMM modules and provide high-speed acquisition of all the various sensor types.